Technology/Product Development Flow

All three divisions of printing and dyeing, soil improvement and plant activation, and fine ceramics are developing, manufacturing and selling technologies and products. We can challenge product development and product improvement that incorporate client’s needs.

-

Interviews

Technical sales staff and engineers familiar with our technologies will listen to your requests. If necessary, we will visit the site in which the product will actually be used in order to properly grasp the environment and conditions. We will then choose the most suitable technology and product.

-

Testing and verification

Based on our interview and surveys, our rock-solid research organization conducts repeated verification tests (ascertaining the structure, checking reactions, analyzing, developing, verifying results). We then try to develop innovative products with more accurate, more precise, more valuable technology.

-

Follow-up

After delivery, if you have any trouble with our products, feel free to contact us. We also provide advice on usage to help you make the best use of their performance and effects. It gives us the greatest pleasure to see our clients satisfied with our technologies and products.

Case Studies

Printing and Dyeing

-

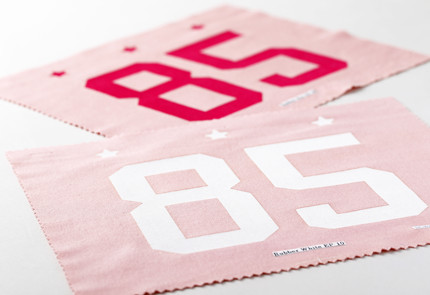

Pretty prints on elastic fabrics

Mainly used for applying logos on T-shirts and sportswear, our solution is flexible enough to retain its shape without cracking, even on stretchy knit fabrics. We use resin inks for white mark printing and mat color printing.

-

Aiming to achieve a sense of fashion through surface design of textiles

We have technologies to give polyester ripple effect or transparent appearance or make it crinkly. With these processes, textiles can be given a range of expressions. In this process heat-expanded film formation ink is applied to the textiles, and then heat is used to soften and deform the fibers into the desired shape.

-

Rejuvenating the resist-printing agents used for screen printing

Conventional activated carbon resist-printing agents (which work through adsorption) are not suitable for auto-screen printing or rotary screen printing due to the poor coloring of dyes and the properties of the activated carbon particles. So we have developed a brand-new resist-printing agent that doesn’t use activated carbon and which physically prevents dye penetration.

-

Dots coloring for diverse expression

Referred to as single-unit multi-color speck printing, this technology comprises an encapsulated agent for dispersion, acid, reactive, and cation dyes. Encapsulated dyes enable dots coloring respectively.

Soil improvement and Plant activation

-

Soil improvement agent

As the agent is watered to the soil, it instantly gives the soil a more porous, aggregate structure. It improves; water permeability, water holding capacity and air permeability.

-

Soil penetrant and wetting agent

These agents help water to permeate through the soil and its colonies of microorganisms. It eliminates water stress for plants and spreads fertilizer etc. through the soil.

-

Turf colorants

These agents are sprayed to color sports turfs and gardens into a natural green. They also melt frost and facilitate growth.

Fine ceramics

-

Dielectric ceramics for microwaves

These ceramic can pass only a limited microwaves. They are used in antennas for satellite broadcasting, GPS, and portable communication devices such as cellphones. Dielectric ceramics are expected to be an area of further advancement.

-

PZT piezoelectric ceramics

It is a ceramic that expands and contracts when electricity is applied. This has applications in high-resolution speaker, ultrasonic diagnosis devices, fish finders and ultrasonic sensors.

-

Ceramics PTC

PTC ceramic is resistance value rises sharply when electricity is applied. These products are mainly used for heaters, overheat protection and overcurrent protection.

-

Ceramic capacitors

It is a ceramic that charge and releases electricity. This is essential for electronic devices, as it is used in substations and blinking lights ― and especially in electronic circuits.